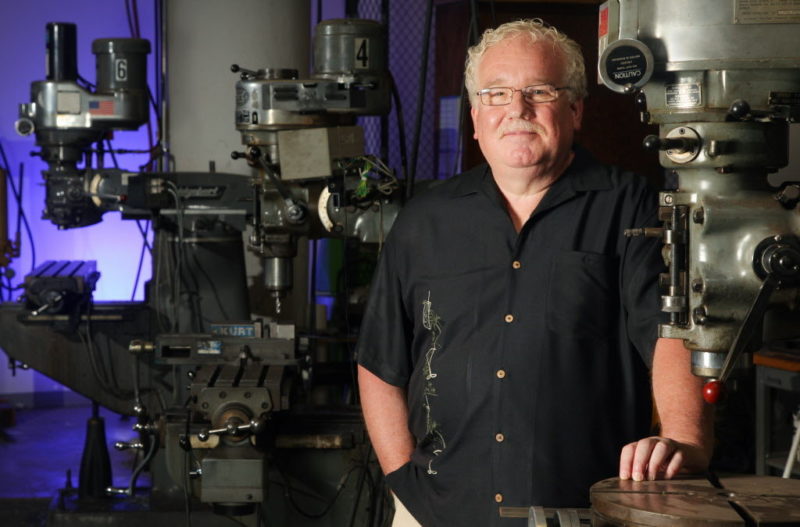

Cleveland Whiskey has developed disruptive technology to dramatically accelerate the maturation and flavor development of distilled spirits. Our process creates a flexible and scalable “just-in-time” manufacturing environment, and a better product. Our approach to making whiskey is Radically Different. Some call it sacrilege, but all we care about is taste. We spoke to the Founder and CEO Tom Lix about their technology and how they are radically changing the whiskey market.

Tom, tell us about yourself. What were you involved in before joining the Spirit Distillation world.

Tom, tell us about yourself. What were you involved in before joining the Spirit Distillation world.

TL: Actually I learned distilling over 40 years ago while I was in the Navy. First making fresh water out of salt water but then there was some bootleg spirit work that I won’t get into. Suffice it to say I have some pretty solid experience. After that I ran some marketing consultancies and founded a software company that I was able to sell.

Give us some history on Cleveland Whiskey, LLC. What is the difference between being an LLC or an actual Distillery, if there is one?

TL: An LLC is simply a form of organization, a limited liability company as opposed to a corporation. We formed in 2009, started as a small laboratory and experimentation company but then shipped our first bourbon in March of 2013. We were recently named “Whiskey Distillery Innovator of the Year” at the 2016 Berlin International Spirits Competition.

What exactly does your job entail?

What exactly does your job entail?

TL: Everything. Look, we’re not a craft distillery or a micro-distillery, we’re an innovation company that is using some innovative technology to create finishes that simply have never been available before. I’m certainly involved with the technology but as a small company we all help take out the trash.

What whiskey expressions do you currently produce:

TL: We have some fairly standard bourbons that stand up well in blind tastings against some of the larger brands like Knob Creek but we also do a line of bourbons that are finished with what we call transformative woods. These are woods like black cherry, hickory, sugar maple, honey locus and apple that you could never make a barrel out of (they’d leak like a sieve or at least be exorbitantly priced). But with our technology we can finish bourbons with each of these woods, all with unique and amazing flavors and we do it without sugar, without syrup, without any artificial flavors or colors.

Is there a flavor profile that you aim to achieve when malting, mashing, fermenting, distilling and maturing?

TL: We’re not trying to simply make something that tastes like traditional whiskies but rather trying to expand the box. Remember that anywhere from 60 to 80% of the flavor in a whiskey comes from the maturation process. The interaction of the distillate with the wood which has pretty much always been a barrel, an oak barrel. We’re moving in some amazing new directions.

Tell us briefly about your “Disruptive Technology” to age whiskey?

Tell us briefly about your “Disruptive Technology” to age whiskey?

TL: The key here is that we’ve gone beyond the barrel, it doesn’t limit us or constrain us. That’s definitely disruptive. If you walked through our distillery it would look different (more stainless steel than copper or wood) and certainly sound different. Our process is active not passive and to me that’s the music that I hear from our pumps, our pressure systems and of course the movement of spirits through the process.

Your favorite thing about going into the distillery each day?

TL: We run a small research and development system in parallel with our production systems. With that we’ve been experimenting with woods ranging from pistachio, pear and peach to mesquite, cedar and walnut. Not just the wood itself but how we’ve dried it, what moisture content we use, how we’ve toasted it, whether we char it and if so, how is it done. Its uncharted territory and we get to taste each of these experiments every day. That’s pretty exciting.

What three words do you want people to associate with your whiskey?

What three words do you want people to associate with your whiskey?

TL: Think of it as “Whiskey. Without Limits.”

Talk for a minute about your choice of still – how did you know it would create the flavor profiles you were looking for?

TL: Stills make a difference but not nearly as much as the established players would make you think they do. The distillation is a small part of what helps create a flavor profile and that comes much more from the wood. The toasting, the charring, the rate of exposure and certainly the type of wood that is being used. Not just the type of oak or whether the barrel once held some sherry or port but rather the tree itself. The species, where it grew, the weather conditions that it grew in.

Do you believe now is the most exciting time for a whiskey lover?

TL: It’s always exciting. As long as you can experience new things.

With this market being saturated with niche craft whiskey distilleries, what are you doing to stand out from the mass?

TL: First of all, I don’t think it’s saturated. Second, we’re not trying to be the typical craft distillery. We’re now in 16 States and selling in Germany, France, Belgium, Denmark, Switzerland and Japan. We also recently shipped our first products to China (including some unique ginseng infusions).

What are your hopes for the distillery 5 years from now? What do you want to be known for?

What are your hopes for the distillery 5 years from now? What do you want to be known for?

TL: 5 years for us is an eternity and I’m not sure I can predict that far out. I’d like to be known for breaking down barriers, for not accepting that we can’t do better and ultimately for creating a great company and treating people well.